COVID-19 testing could soon be coming to a parking lot near you.

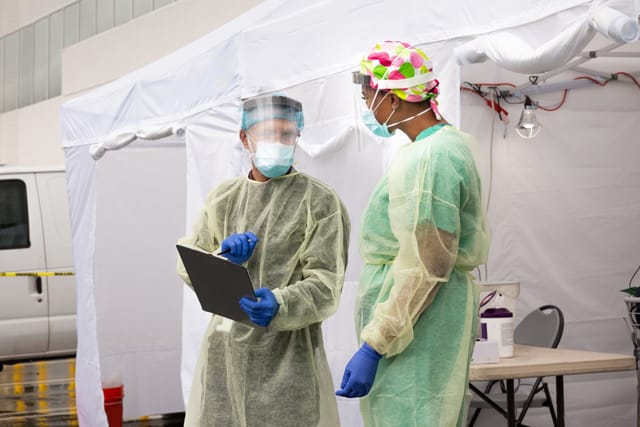

With the growing need for rapid COVID-19 testing, many locations throughout the country have turned to mobile testing sites constructed from former shipping containers.

In North and Central New Jersey, Mobile Health Solutions, an affiliate of Red Bank-based Immediate Care Medical, placed these mobile testing centers in parking lots of shopping centers around the state. The installation of these mobile testing centers was in response to the growing demand of the COVID-19 testing program at Immediate Care, which was testing about 1,000 people a day at its eight urgent care centers.

Construction

The eight-foot-by-20-foot testing centers are constructed completely from former shipping containers. The shipping container clinics typically include anywhere between two to four private testing rooms inside. Each testing room has its own set of doors to the parking lot, and each room also includes its own sink, negative airflow system, heating, and air conditioning.

A typical visit takes ten minutes or less for the entire test. PCR COVID-19 testing is by appointment only in New Jersey with results returned within 48 hours from FDA-approved labs.

Location

The mobile test sites were set up at shopping centers, municipal parking lots, school parking lots and recreation center parking lots.

Sal Cannizzaro, principal of Mobile Health Solutions and Immediate Care Medical, hired R.J. Brunelli & Co, a retail real estate brokerage in Old Bridge, to help guide an expansion into shopping center parking lots and other high visibility sites throughout the state of New Jersey.

Design Studio

The New York office of architecture studio Grimshaw designed a number of the COVID-19 mobile testing units within former shipping containers for healthcare company Osang and engineering company SG Blocks. The design plans were initiated based on the demand to provide increased mass testing during the COVID-19 pandemic.

Referred to as D-Tec, Grimshaw designed five different units that would each utilize the space of former shipping containers. The smallest unit, D-Tec 1, would make use of the space of a single shipping container, while the largest unit, D-Tech 5, would be constructed of five shipping containers.

D-Tec 1 could be designed to include between four to eight collection windows, as well as an information window. Each collection window would be separated by a removable section of wall.

Each of the larger unit designs, D-Tec 2, D-Tec 3 and D-Tec 4, combine the sample collection design of D-Tec 1 with laboratories for analyzing test results or testing clinics with examination rooms.

The largest unit design, D-Tec 5, includes five shipping containers entirely dedicated to laboratory facilities.

Grimshaw chairman Andrew Whalley explained that the D-Tec 5 lab could process 750 tests per hour.

This innovative design constructed from former shipping containers allows for much greater efficiency, an increase in rapid COVID-19 testing and shipping container hospitals in areas throughout the country.